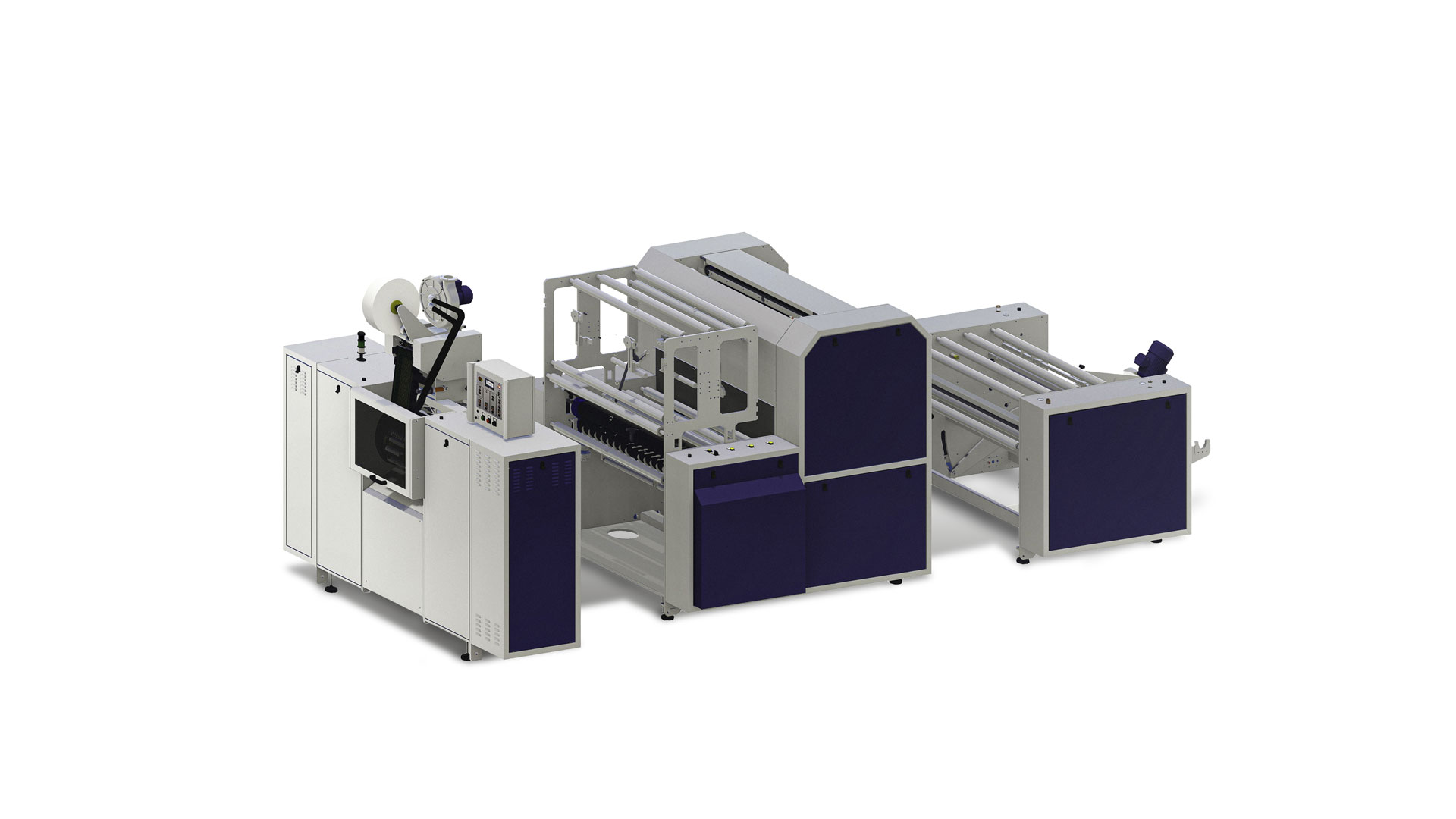

KARO 900

Roll-making machine KARO 900 MONO

Roll-making machine for the production of plastic bags. Thanks to the double-sided sealing technology, we achieve a high quality of the bags produced, irrespective of the film thickness.

- Intuitive operation of the machine via a touchscreen operator panel.

- Reliable operation controlled by a PLC.

- Quick parameter change (bag length, sealing temperature, speed) without stopping the machine.

Additional equipment

The machine is used to affix a paper label during the production of roll-fed refuse sacks. The paper label wound on the roll is printed on one side and covered with water-activated adhesive on the other.

The function of the label applicator is to measure the programmed length of the label, cut it off (from the roll), moisten the adhesive side and wrap the roll of refuse sacks.

-

- Max. number of rolls/min 10pcs

- Max. label width: 140 mm

- Max. label length: 500 mm

- all parameters are controlled via a touchscreen operator panel

- the label applicator is equipped with a print reader, enabling it to cut the label at a specific, fixed point.

See the machine >

It is used to automatically and continuously adjust the position of the film in relation to the machine axis.

See the machine >

The type 1V folding unit allows the film to be folded in half. Its design allows it to be mounted on the unwinder or as a free-standing element between the unwinder and the sealing unit.

See the machine >

Technical data

Size:

- length 6200 mm

- width 2400 mm

- height 1880 to 2300 mm depending on configuration

- weight 5400 to 6000 kg depending on configuration

Energy requirements:

- Installed power 19,5 kW, 3x380 V, 50Hz, PE+N

- Compressed air 360 Nl/min

Capacity: 100m/min.

Parameters of the finished product

Bag length electronically adjustable: 580 – 3 000 mm

Max. width of sealed strip: 1 x 900 mm

Max. width of finished roll: 1 x 500 mm

Max. roll diameter: 160 mm

Max. number of rolls/min: 10 pcs

Product types

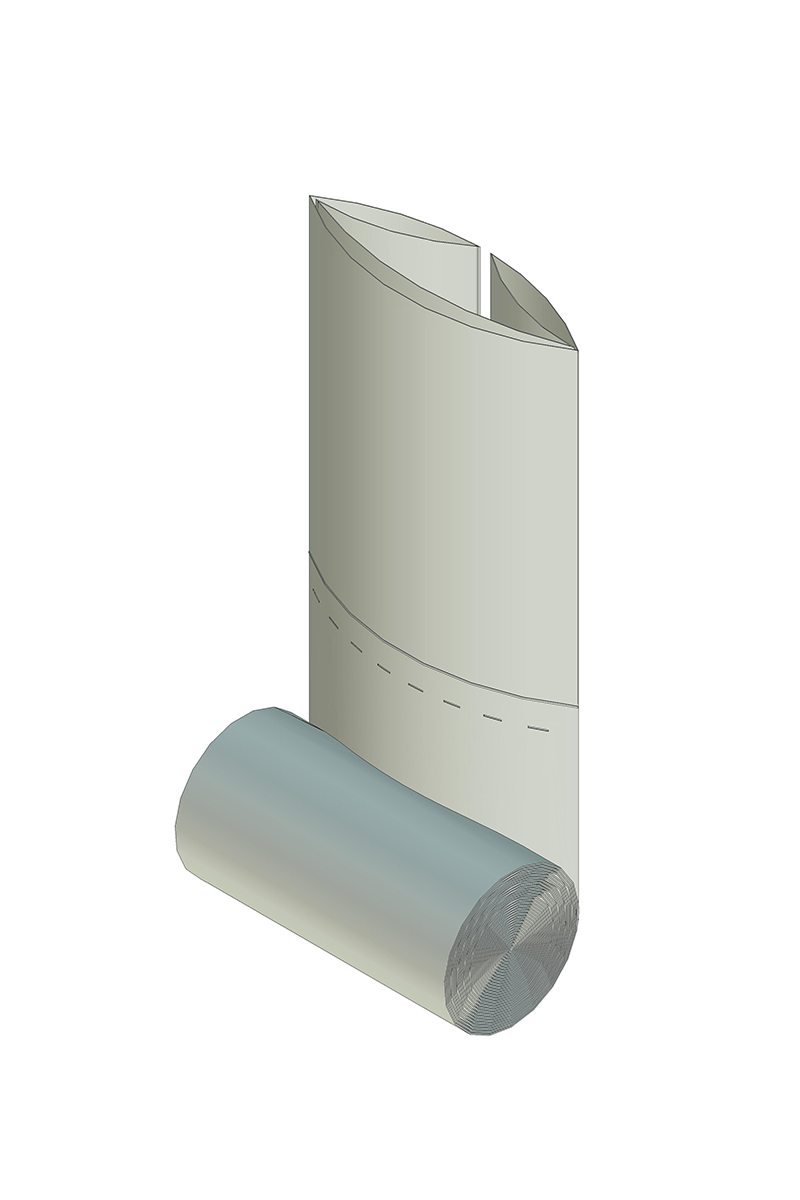

Type 1xC Bag

Type 2xC Bag

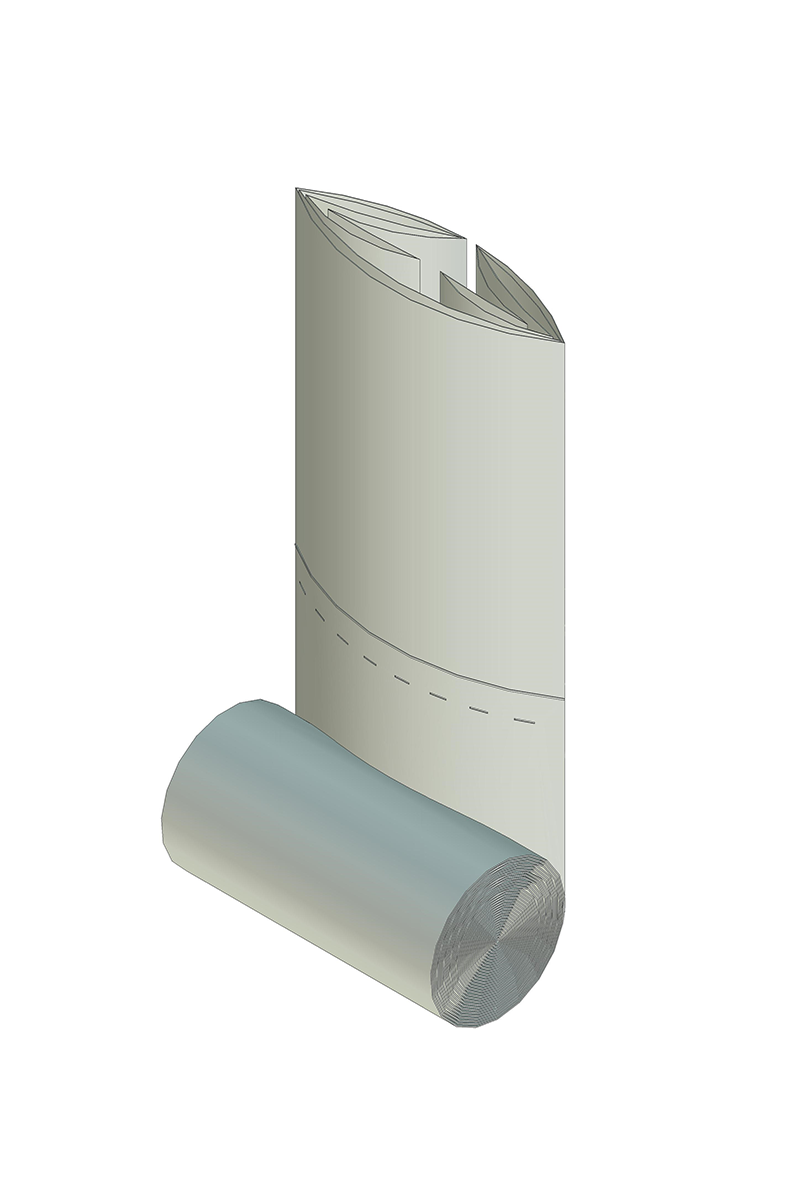

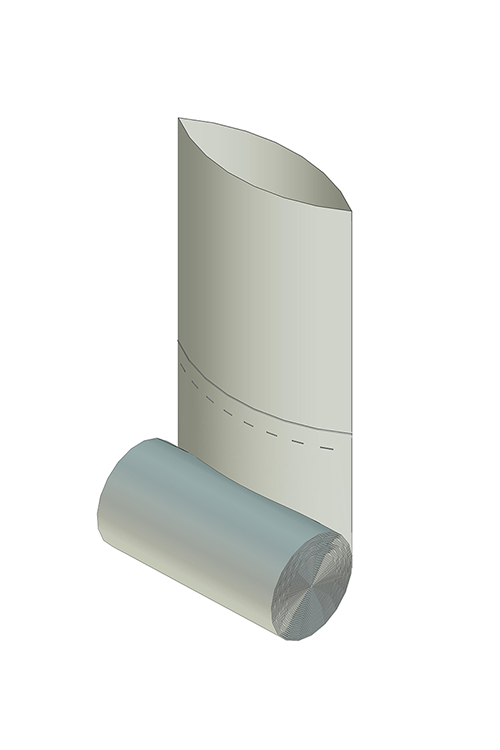

Star Bag

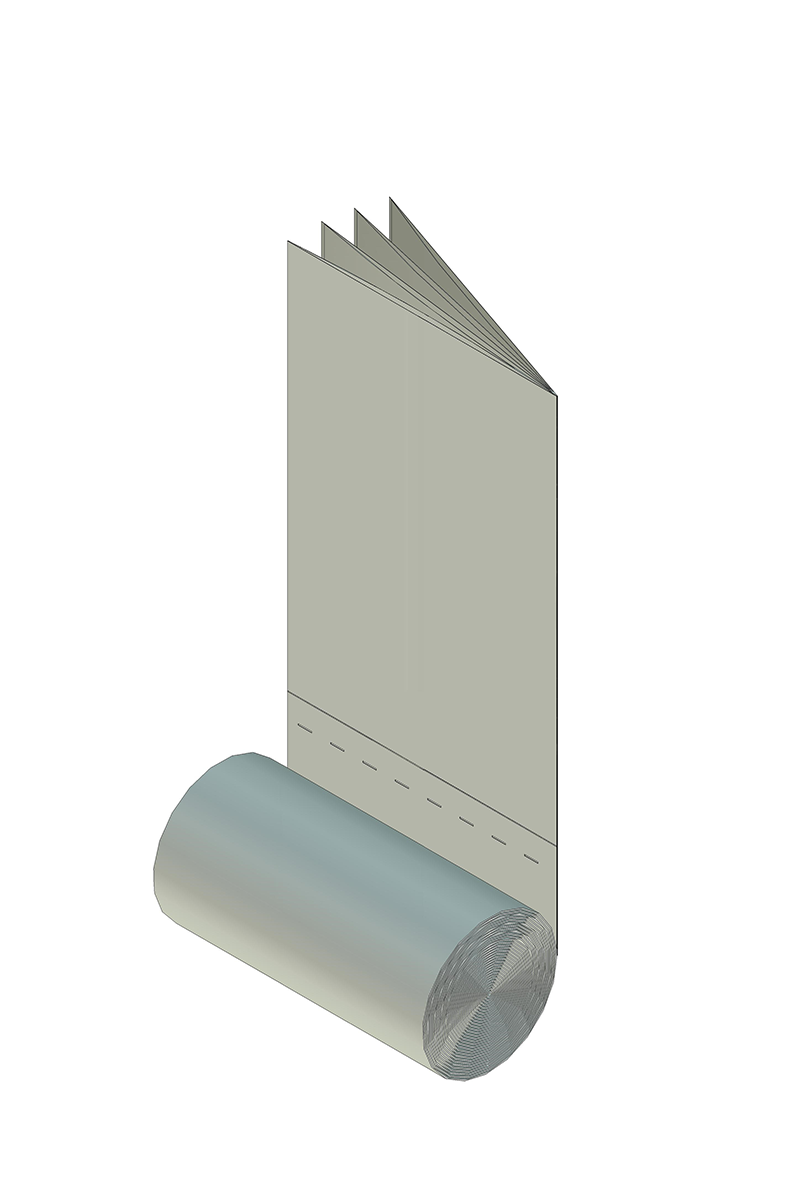

Regular Bag

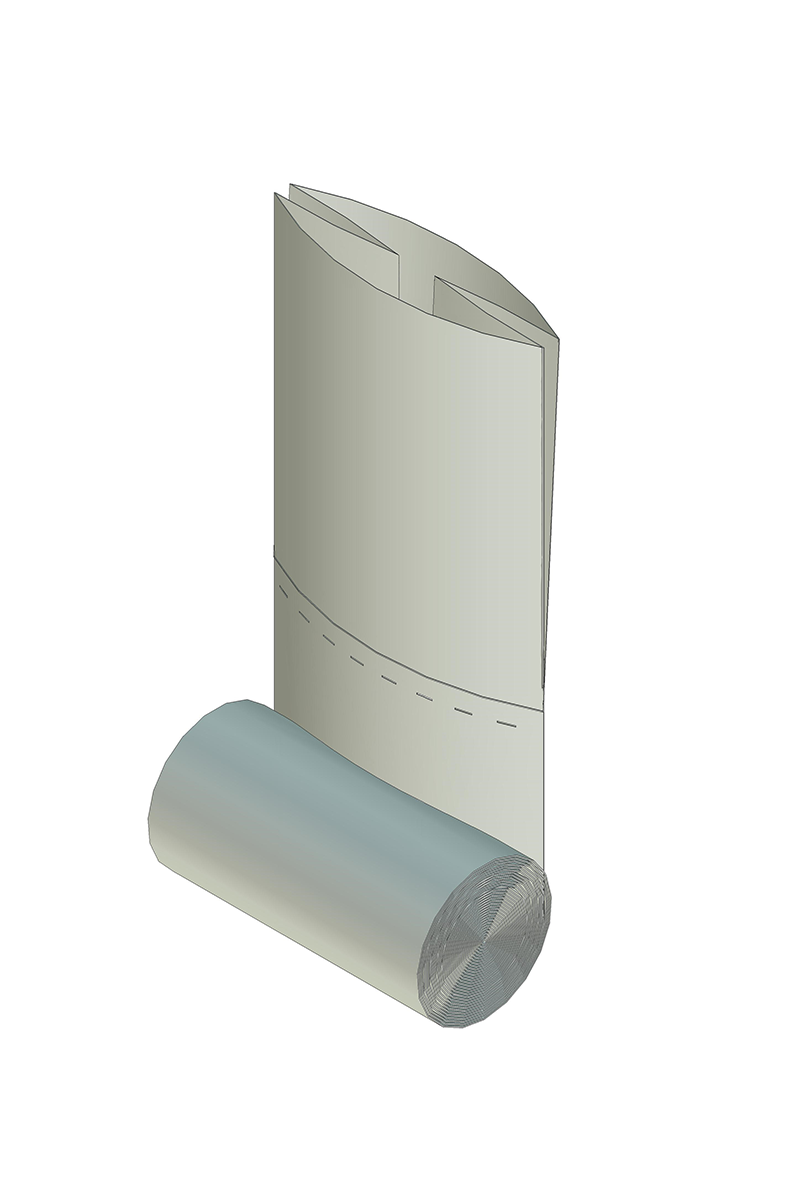

Side-fold Sack